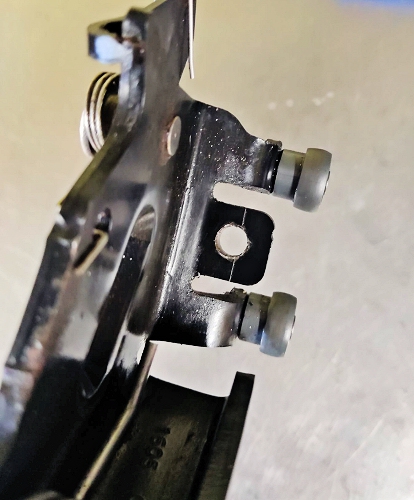

If one of the tyres on the ROLLERS becomes worn or split then bear in mind that the load is taken mostly by the centre ROLLER. Check by fully opening the door and watch the ROLLERS rotate as the door starts to close.

Always clean the GUIDE RAILS - do NOT oil/grease them. Should the paint get wrinkly or worn; using a flat file and emery paper, gently rub down the lower running surfaces until they are smooth. Up to you if you repaint them; I don't myself.

Most problems seem to be with the centre ROLLER. I've not heard of many problems with the lower ROLLER - but with the door open you might grovel on the floor and look upwards to see if the lower GUIDE RAIL is clean and clear of obstructions.

Unless you have too many, be careful with fingers at all times and make sure you have all remote key fobs in your care so no-one else can "help" by moving the doors whilst your fingers are in there.

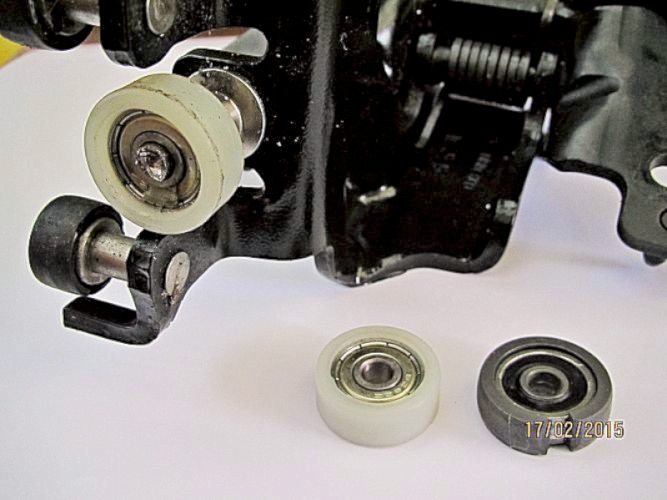

This is the hinge assembly that runs on the centre (middle) GUIDE RAIL; the larger ROLLER takes more than half of the load of the heavy door, and is usually the first to fail.

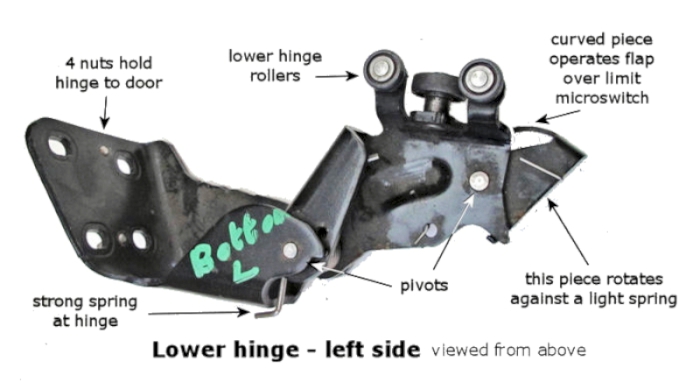

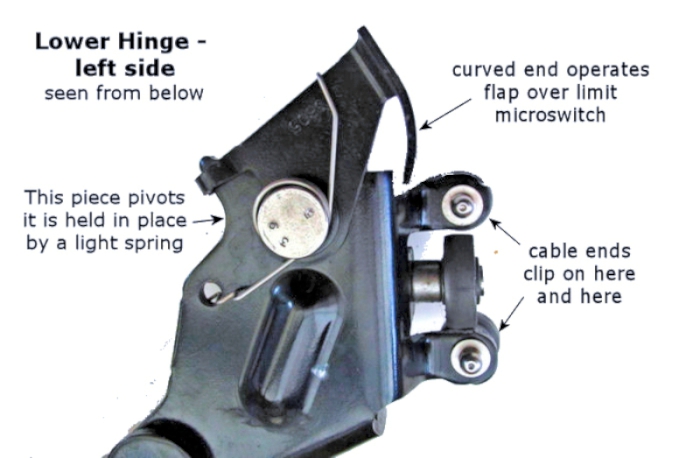

The lower hinge assembly supports the door and also transmits the movement of the open/close motor-driven cables to the door.

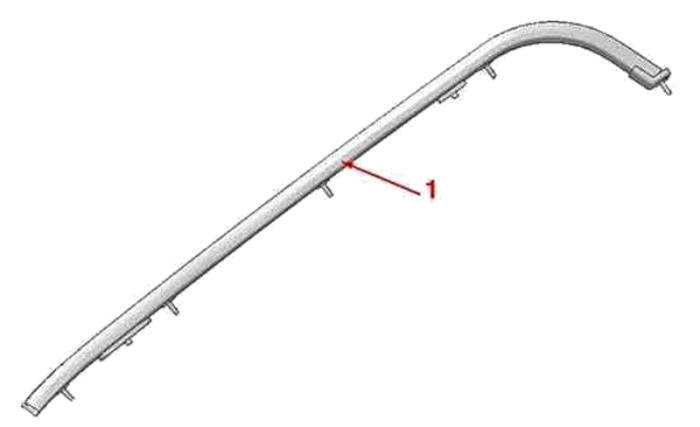

The upper guide locates the top of the door and I have yet to hear of a failure.

I oiled the ROLLER bearings on one car and the vital large ROLLER and the paint on the GUIDE RAIL running surfaces failed on both sides about two years later. Possibly some oil did stray onto the roller and guide surfaces though I thought I had cleaned them off.

Worth repeating - clean off any surplus oil and dirt from the GUIDE RAILS as the rollers need friction (not lubrication) in order to rotate - if they don't rotate they will quickly form a flat and a knocking noise as the door moves.

. . . . unless you want your ROLLERS to look like this: . . . (a rare occurrence)

this was a ROLLER that ran in the lower GUIDE RAIL (not mine!). Possibly the bearing had seized as this ROLLER is very low down and may have seized over the years.

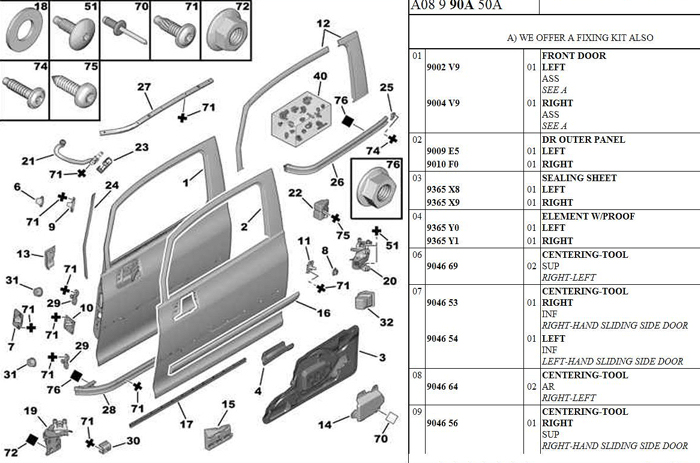

At the moment, (2015) complete new middle hinge assemblies, part numbers 9033S8 (left) and 9033S7 (right) are available from Peugeot for about £78 including VAT each. In 2018, these parts have increased £106 including VAT

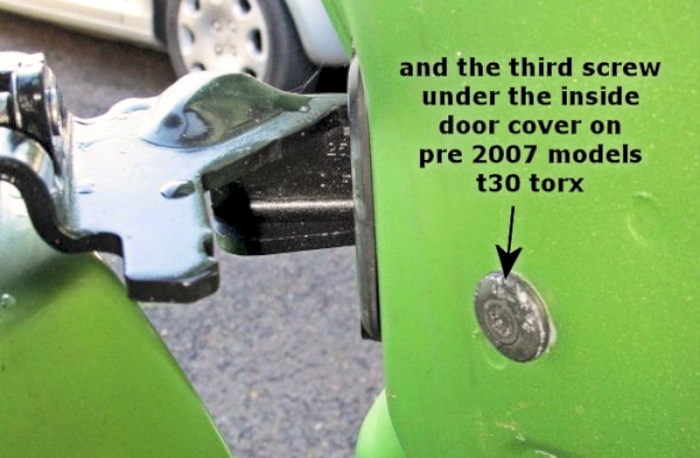

both middle door ROLLERS on the green car (50,000 miles) had split their nylon/rubber running surfaces NOTE THAT the original ROLLER assemblies had a third bolt under the door cover so the door covers have to come off early cars as well, but the job is fairly straightforward.

New middle ROLLER assemblies only use two mounting points so will be much quicker to change next time as the inner door covers don't have to come off.

remove the corner trim by removing the Torx30 bolt and unclipping as shown

This is the third T30 bolt (2005/6 models only) which means the door cover has to come off to remove.

Support the door as the central ROLLER you are removing takes the full weight of the door

Make this a firm support as the door may try to pivot away when you remove the central ROLLER; I have the dent to prove it.

after removing the three bolts (two on later cars) the hinge with rubber seal pulled out against spring pressure (careful wih fingers) and was easy to slide off the GUIDE RAIL.

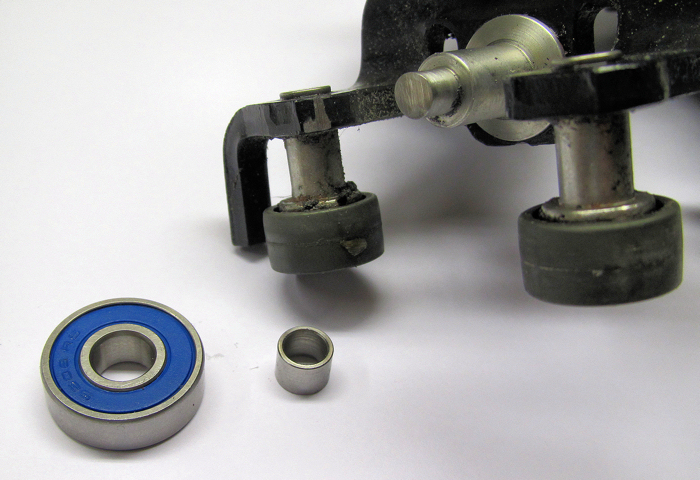

As new hinges were no longer available by 2024, I fitted a new tyreless roller in this manner:

The roller is available on

Amazon:

"Sourcing map 628-2RS Deep Groove Ball Bearings 8mm

x 24mm x 8mm Double Sealed Chrome Steel P6(ABEC3)

2pcs"

NOTE: these bearings have Outer Diameter: 24mm; Inner Diameter: 8mm; Width: 8mm and have no "tyres" so should last well. The sleeve is a simple spacer to fit the larger bearing on to the resulting stub. In practice, it rolls smoothly, with a slight, but not obvious, harshness.

The sleeve is available on

Amazon:

"PATIKIL M6 Stainless Steel Spacers, 5 Pcs Metal

Spacer Stainless Steel 6.1mm ID x 8mm OD x 6mm L

Stainless Steel Spacer Screw Standoff Round for 1/4"

or M6 Screw Bolts"

First clean the hinge removed from the car (or a second-hand "spare" hinge).

Then grind off the end of the spigot holding the faulty roller and remove the old roller.

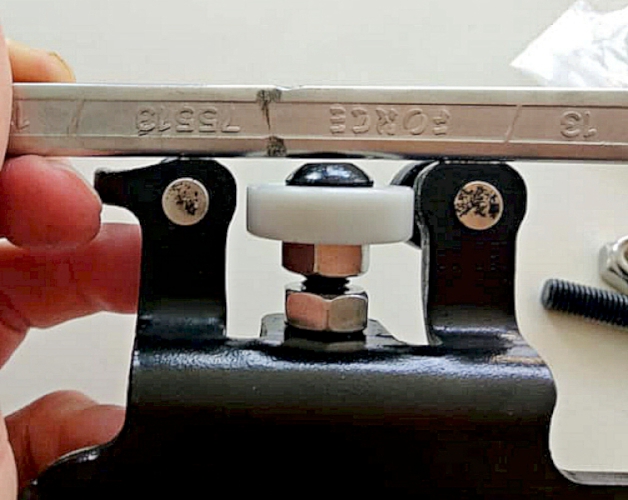

This shows the sleeve and bearing ready to fit onto the spigot.

You are about to glue the bearing onto the spigot, so emery paper and clean the touching surfaces.

Glue the sleeve and bearing onto the spigot (I used normal Araldite, which is strong and well-proven).

Allow the glue to set (24 hours for Araldite) and refit the hinge assembly to the car.

Other solutions are suggested below, but the one above appears to be a cheap and simple way to replace the middle roller.

One trick is to push the tread off a new roller - they are quite tough. A little gentle heat will help.

Build an assembly like this: The washers have to be of the correct diameter - that is the same diameter as the bearing but smaller than the nylon tread - so they press on the outer ring of the bearing, not the tread.

Put the assembly in the vice and press off the tread.

I did one myself - using a 12mm socket which just fits inside and presses on the bearing and a 19mm socket to press on the tread itself.

The tread pressed off easily enough in the vice.

To get the tread onto the original bearing I had to open up the inside slightly and chamfer the leading edge - the material is quite tough and I found the best way was on the lathe.

After doing this I pushed the tread on (using the 19mm socket the other way around) in the vice with a little force - I didn't glue mine as it seemed quite tight enough.

Fitted September 2017 as the "new" Peugeot one had already started to split. Initial impression is that the white tyre makes no more noise than a new Peugeot one.

However it has become increasingly noisy so in June 2018 was replaced by a new hinge assembly (see above). On inspection, the new roller surface had become slightly "lumpy" and with the harder material was making excessive noise.

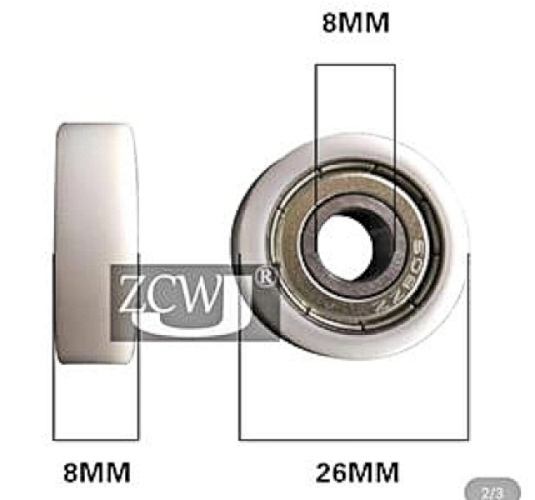

This is the roller size to get for

this modification.

The bearing it is based upon is a 626ZZ

Currently (2019) this size of roller with a tyre is not available in the UK, but there are Chinese sources

Remove the existing roller and pivot from the hinge - needs some grinding to clean up.

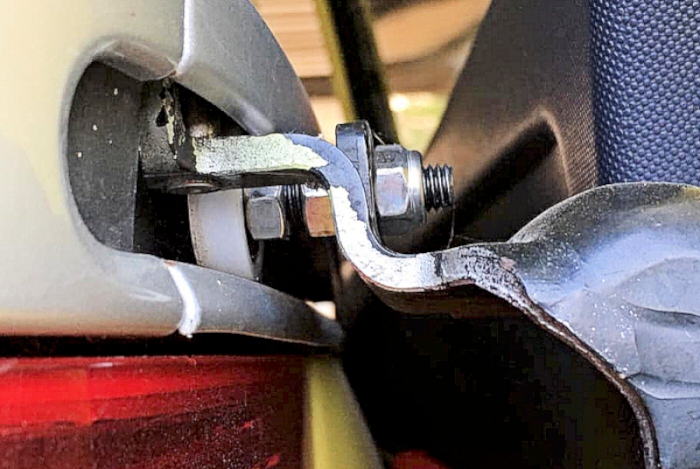

Then using a high tensile bolt with nuts as spacers, assemble as shown below.

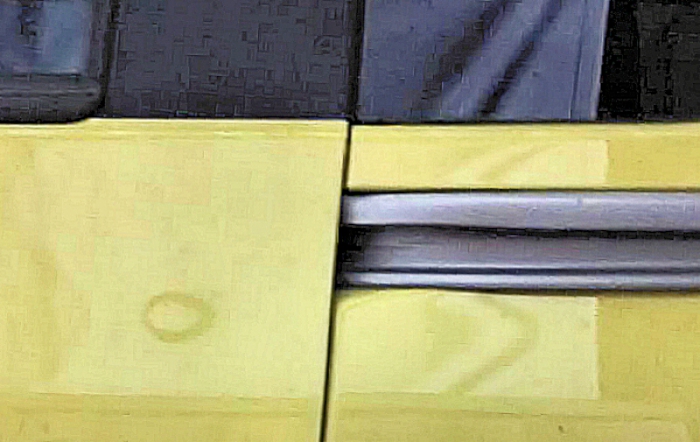

Original rollers are 24mm diameter - will a larger 26mm diameter roller fit, to allow use of a stronger 8mm centre bolt?. . . . . . YES!

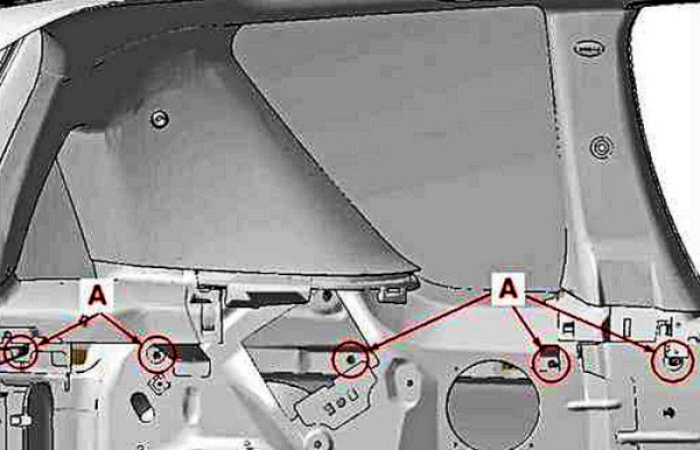

The centre guide rail is item 26 on this drawing

From what I can see on the drawings; the nuts holding the rail have to be taken off from the inside (which means removing the interior trim).

This is a really nasty dent; body repair will probably mean welding in another section and replacing the guide rail.

Remove the centre rollers first and support the door partially open.

The guide rail is held in place by studs on the back of the guide - which means it has to come off by pulling outwards.

Note: this picture shows the inside of the left-hand body.

To remove the guide rail it is necessary to take out the internal trim and speaker to get to the five M6 securing nuts.

The nut holding the seat belt unit might also need to come out as it in the way. NEVER open the side with the spring (bulged) to loosen it when reinstalling (otherwise you could end up buying a new seat belt!) but open the opposite side and push open a locking mechanism then the belt slackens easily.

At the moment, (2015) complete new lower hinge assemblies, part numbers 9033Q3 (left) and 9033Q2 (right) are available from Peugeot for about £90 + VAT each.

This is a spare lower hinge assembly

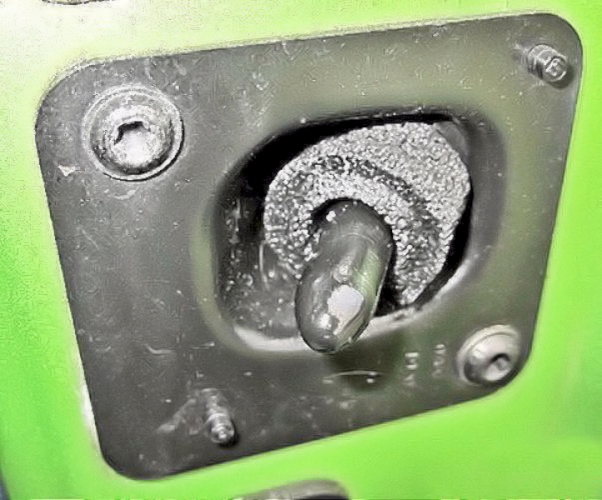

When closed, the door is located by three spigots which locate into sockets.

This one is low down on the "B" post

The one above and this one at the front of the door are fitted with a soft spongy washer to take up any slack and minimise rattles.

this spongy rubber is quite critical as when the door is closed, it compresses the washer and prevents the spigot rattling around in the fixed location guide

If the spongy rubber has disappeared over the years, I have used spongy dishwasher pads and cut them up to fit. Not ideal but better than nothing!

The third spigot (not shown) is at the front of the door about eye level and fits into the matching slot on the A post.